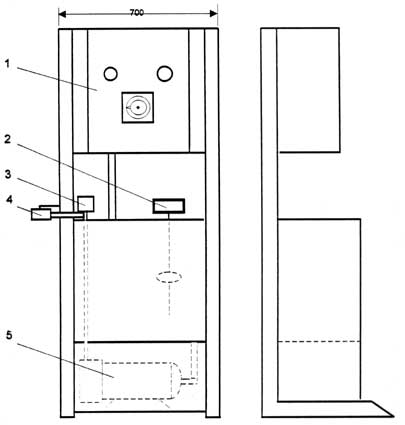

TESTRÍ mixing and supplying station, maneuverable, equipped with a TESTRÍ-MIX two-component mixing set, model TM K2-au-1500 HL

|

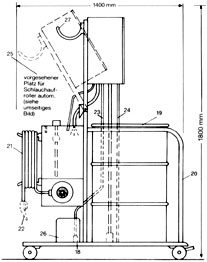

TESTRÍ-MIX mixing and supplying stations for two or three components, maneuverable or static, are used for the production and forwarding of aqueous materials (emulsions and solutions, e.g. coolants) used for cutting and grinding operations, no matter if for new filling or refilling. The stations work fully automatically and are switched on and off by the filling pistol (one-man operation). |

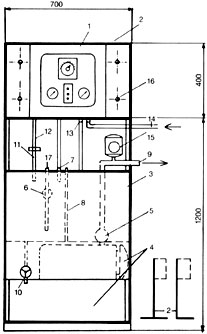

TESTRÍ central mixing and supplying station, equipped with TESTRÍ-MIX two-component mixing set, model TM K2-au-3000 HL.

|

Advantages of these TESTRÍ Mixing and supplying stations that guarantee an optimum economic efficiency: |

|

MVS Console TESTRÍ Mixing and supplying station (mixing set selectable) |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||